STAINLESS STEEL CUTTING AND WELDING MATERIALS IN NIZHNY NOVGOROD

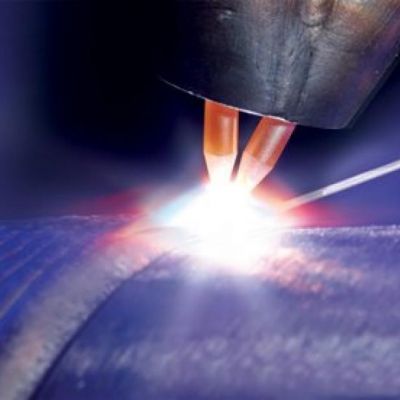

Special tools and consumables are used for cutting and welding. They are used for preparatory work (metal cutting, stripping and grinding of the cut surface and the surfaces to be welded), directly welding process and finishing works (removal of scale, cleaning of the surface of the product, stripping and grinding of the welding seam).We supply a number of necessary materials used in these processes, including:

electrodes. In our assortment there are tungsten electrodes and electrodes for black and stainless steel. Tungsten electrodes are designed for argon arc welding of black and stainless steel. We supply lanthanated (WL), thoriated (WT) and iridiated electrodes manufactured by Elga (Sweden). Electrodes for welding black and stainless steel Cromarod 316L of the same company with rutile coating can be used for welding on vertical surfaces and on the ceiling. They form a seam with high corrosion resistance and are suitable for welding acid-resistant AISI 316 steel;

stripping discs for removing materials from steel surfaces (paint, rust, etc.), preparation for welding, grinding, processing of welding seams;

stainless steel cutting discs. White electrocorundum on a bunch of bakelite was used as an abrasive. The tool provides stable cutting and smooth cutting surface. The diameter range from 115 to 230 mm provides the possibility of application in domestic angle grinders (grinders) and industrial equipment;

stainless steel welding wire. It is used for argon arc welding (Cromatig 308LSi and Croimatig 316LSi) and semi-automatic welding (Cromamig 308LSi and MIG 316) produced by Elga. The welding seam has high quality and is practically not subject to intercrystalline corrosion due to the content of silicon and carbon additives in the additives;

steel brushes for scale removal, paint layer, rust, run-off colors, deburring, stripping of welding seams. They are made in the form of nozzles or have a rotating element. You can choose a model for the treatment of hard-to-remove dirt, large surfaces and hard-to-reach places.

All supplied products for cutting and welding are of high quality, characterized by versatility, economical consumption, long service life and ease of use.